Description

The activated-carbon adsorbers of the CLEARPOINT V series are particularly suitable for large volume flows and high pressures. They are convincing on account of a minimum residual oil content of only 0.003 mg/m³ and low differential pressure with extremely low energy costs.

Economic oil-free compressed air with activated carbon adsorbers

In order to ensure high compressed air quality with compressed air class 1-2 in accordance with ISO 8573-1, in particular with regard to the residual oil content, the CLEARPOINT V activated-carbon adsorber is the effective and reliable technical component in demanding system designs.

The consistent overall concept guarantees compressed air quality with a minimum residual oil content extremely cost-efficiently. Oil vapours and odours are adsorbed on the unusually large active surface of the compression-moulded activated carbon pellets. When selecting our activated carbon, we work together with selected suppliers who guarantee consistent carbon quality. A major advantage for your compressed air quality and process reliability.

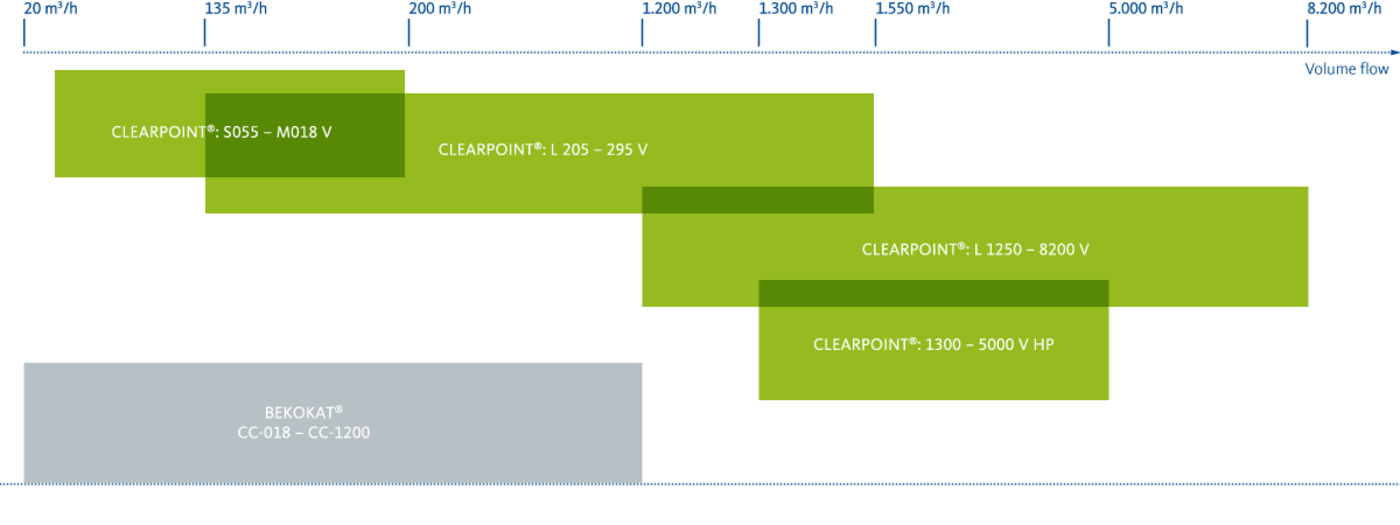

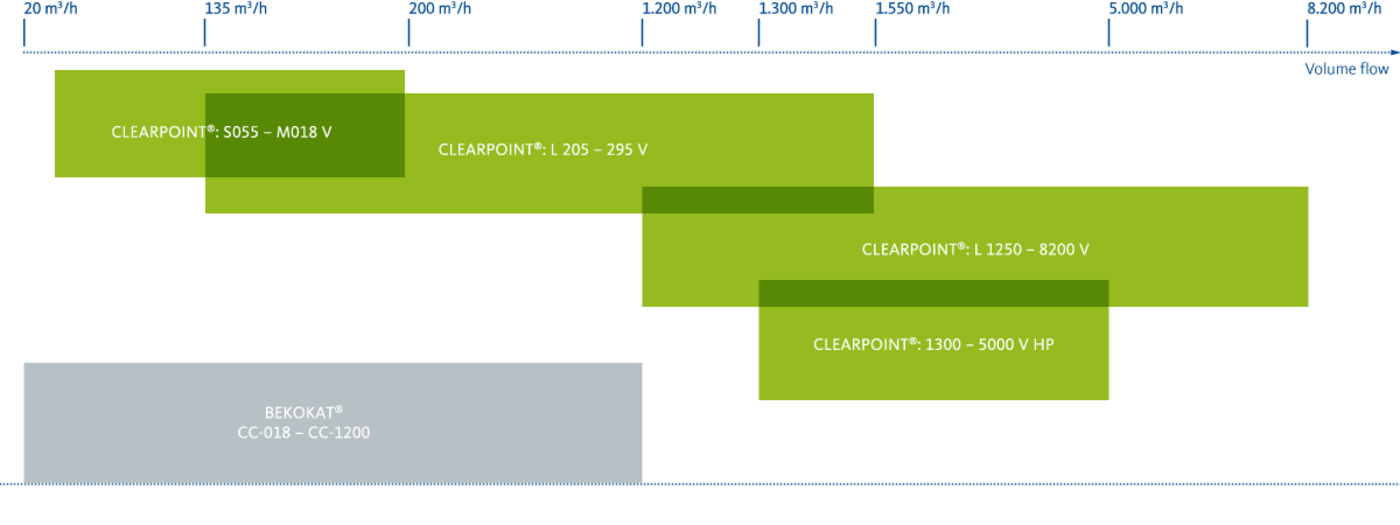

Depending on the compressed air volume required, BEKO TECHNOLOGIES can offer you the suitable solutions

CLEARPOINT® V S/M activated carbon cartridges

CLEARPOINT V activated carbon cartridge for small and medium volume flows

For small and medium volume flows up to 200 m³/h and pressures up to 50 bar [g], our CLEARPOINT V S/M offer a clean solution for oil-free treatment.

A special activated carbon cartridge has been developed for maximum requirement profiles.

- Highly efficient adsorption with minimum residual oil content

- Significantly higher service lives than conventional activated carbon filter elements

- Service-friendly with easy to exchange cartridge

- Conventional testing technology can easily be adapted

CLEARPOINT® V L activated carbon adsorber

CLEARPOINT V activated carbon adsorbers for large volume flows

The extraordinary range of variants of the CLEARPOINT V L available offer you the suitable solution for every requirement. For volume flows up to 8200 m³/h and pressures up to 40 bar [g].

CLEARPOINT V L is the effective and reliable solution for ensuring a high compressed air quality, particularly in terms of the residual oil content. An indispensable technical component in demanding system designs. Advanced overall design for outstanding performance.

In addition to our standard versions L 205-295 V, L 1250-8200 V for volume flows from 135 m³/h to 8200 m³/h, we also offer a suitable option for the pressure range up to 40 bar in the form of our L 1300-5000 V HP (1300 – 5000 m³/h). If particular care is required in terms of fire protection, we can deliver all models in a VH version on request, which provides a combustion-resistant solution thanks to special carbon.

Advantages of CLEARPOINT® V L activated carbon adsorbers

Economical

- low operating costs

- low differential pressure

- long service life

Efficient

- efficient oil vapour adsorption with special activated carbon for max. residual oil content of 0.003 mg/m³

- complete solution with oil-free dust filter

Options

- oil test indicator or

- METPOINT OCV compact – residual oil content monitoring to safeguard production processes

Technical data CLEARPOINT® V

| Activated carbon filter with cartridge | Activated-carbon-adsorber | Activated-carbon-adsorber | High-pressure-activated-carbon-adsorber | ||

| Parameter | Unit | S055 – M018 VWM (HP) | L 205 – 295 V L 205 – 295 VWM L 205 – 295 VH | L 1250 – 8200 V L 1250 – 8200 VWM L 1250 – 8200 VH | L 1300-5000 V HP |

| Volume flow* | m³/h | 50 … 200 | 135 … 1550 | 1250 … 8200 | 1300 … 5000 |

| Max. operating pressure | bar [g] | 16 (optional: 50) | 16 , L 295 V: 11 | 11 | 40 |

| Max. operating temperature | °C | 45, recommended less than 25 | 50°C, recommended less than 35 | 50°C, recommended less than 35 | 50°C, recommended less than 35 |

| Max. service life | h | 2.000-3.500 | 10.000 | 10.000 | 10.000 |

* By connecting several activated carbon adsorbers in parallel, respective higher volume flows can be processed.

Reviews

There are no reviews yet.