Description

Separating condensate always provides a solution when, due to the composition, the processing after the purely physical, gravity separation is insufficient for the purpose involved. This is generally the case with stable emulsions, which often result from mineral or synthetic compressor oils in the compressed air condensate. For this purpose, the emulsion-containing wastewater is flocculated in the emulsion splitting plant via a non-toxic, natural splitting agent.

The solution: splitting instead of separating

The BEKOSPLIT emulsion splitting plant enables reliable, economical and company-internal processing of emulsified condensate, which has resulted from unfavourable initial operating conditions or due to certain lubricant-compressor combinations. Insoluble in water organic contaminations and soiling like oil and solid contamination will be removed by the addition of a special splitting agent. The discharged water can subsequently be safely routed into the wastewater sewer system. This has been confirmed to us by the Deutsche Institut für Bautechnik (DIBt).

German type approval

The legislator demands a professional, responsible and safe handling for the discharged condensate. Our BEKOSPLIT emulsion processing plants combine environmental protection and cost-effectiveness for the disposal of emulsified condensates. They thereby enable legally compliant, environmentally friendly and cost-effective condensate processing directly at the point of origin.

Environmentally friendly reaction splitting agent

The wide-ranging highly effective reaction splitting agent (pH 4 up to 10) makes continuous pH value adjustment unnecessary. Chemicals are therefore also not required.

Filtration via bag filter

Increased degree of drainage by utilising larger filter surfaces. Filtration via bag filter reduces the filter consumption and the filter can be exchanged quickly and easily.

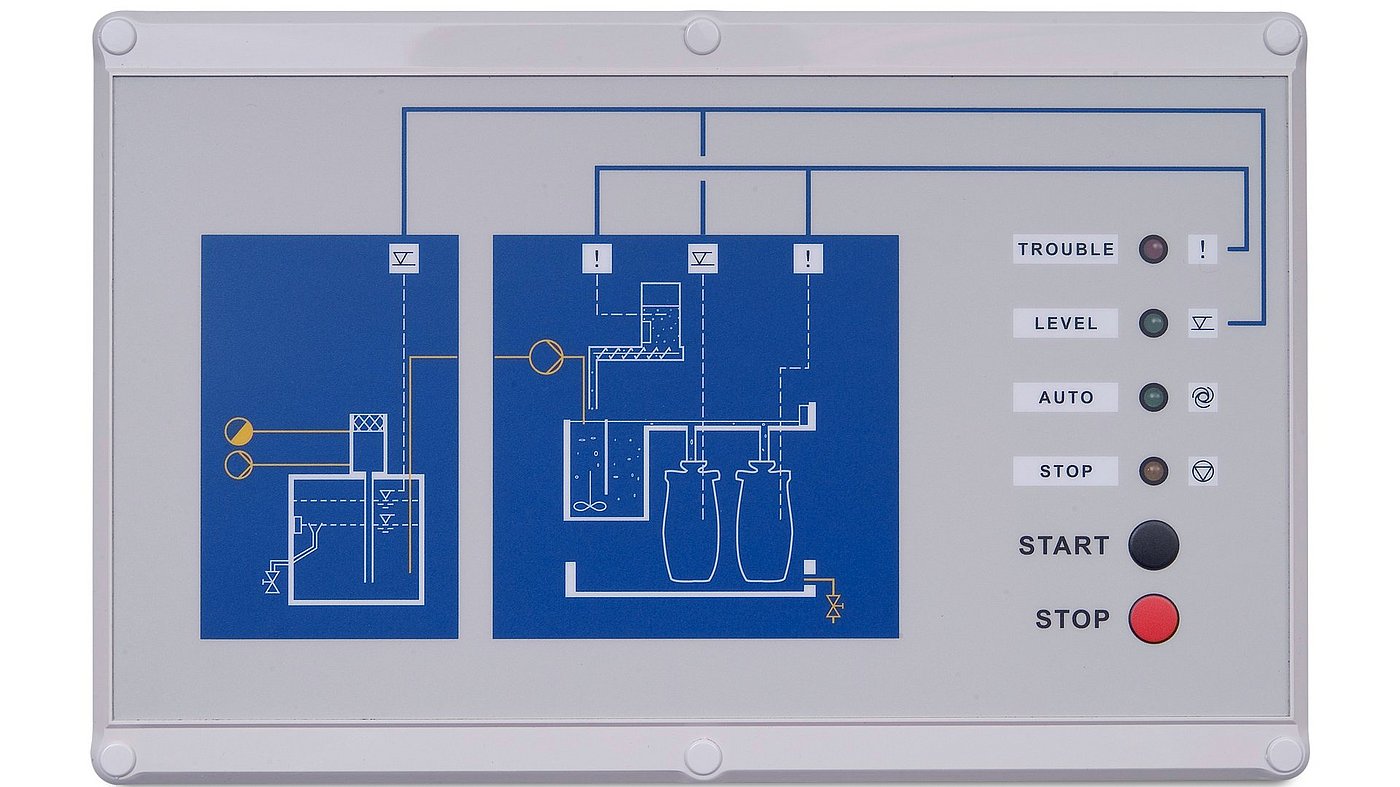

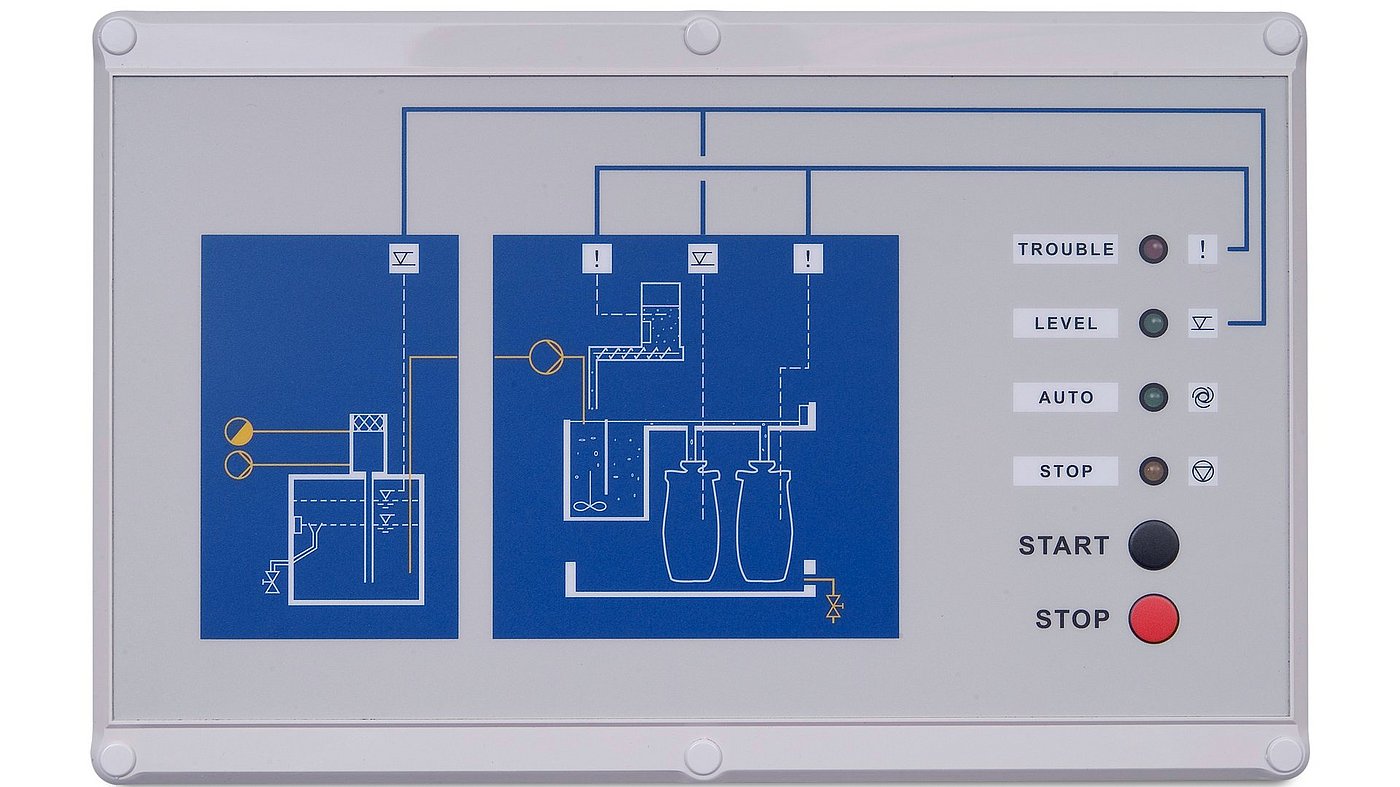

Electronic monitoring

The stock of splitting agent and filters are continuously monitored. Maintenance and malfunction messages can be externally processed via signal outputs.

Advantages of BEKOSPLIT® splitting plants

Economical

- drastic reduction of waste quantities to less than 0.5 percent

- legally compliant and cost-effective condensate treatment directly at the point of origin

- amortisation within 6 months due to savings in disposal costs

Safe

- fully automatic operation

- operating status shown on display

- sensor-controlled fill level monitoring

- signal contact for maintenance and malfunction

Practical

- compact design for space-saving installation

- easy to service

- easy removal of the filter due to bayonet lock

- easy filling of the dosing unit with reaction splitting agent

Ecofriendly

- highly effective reaction splitting agent

- no aggressive cleaning agent required

- high purified water quality

Technical data BEKOSPLIT®

| BEKOSPLIT | 11 | 12 | 13 | 14 | 14s | 15 | 16 |

| Maximum plant performance | 15 l/h | 30 l/h | 60 l/h | 90 l/h | 90 l/h | 120 l/h | 160 l/h |

| Maximum compressor performance | 12,5 m³/min | 25 m³/min | 50 m³/min | 75 m³/min | 75 m³/min | 100 m³/min | 135 m³/min |

| Reaction tank / Filling volume | 10 l | 10 l | 22 l | 22 l | 22 l | 54 l | 54 l |

| Splitting agent tank capacity | 2 l | 8,5 l | 8,5 l | 8,5 l | 25 l | 40 l | 40 l |

| Dimensions (mm) | 433 x 920 x 1160 | 417 x 480 x 1155 | 433 x 920 x 1433 | 433 x 920 x 1433 | 433 x 920 x 1433 | 630 x 1000 x 1483 | 630 x 1000 x 1483 |

| Weight (empty) | 48 kg | 33 kg | 54 kg | 54 kg | 55 kg | 76 kg | 76 kg |

* refer to downloads for additional performance data: Product Folder

BEKOSPLIT® consumables

The reaction splitting agent will absorb the integral oil from the condensate during the process and eventually be saturated and then can be disposed of. We can provide you with two different standard reaction splitting agents. We will be pleased to advise you about an exact selection of special solutions.

Reaction splitting

| Splitting agent | Packaging unit | weight | Order number |

| FL 02 | 1 | 10 kg | 4020598 |

| FL 02 | 1 | 25 kg | 4020596 |

| FL 11 | 1 | 10 kg | 4021427 |

| FL 11 | 1 | 25 kg | 4021430 |

Filter kits

| BEKOSPLIT | 3 | 5 | 11 | 12 | 13 | 14 | 14S | 15 | 16 |

| Replacement filter kit | 4012870 | 4012870 | 4012868 | 4012868 | 4012870 | 4012870 | 4012870 | 4012870 | 4012870 |

| Replacement fleece filter kit | 4012869 | 4012869 | 4012867 | 4012867 | 4012869 | 4012869 | 4012869 | 4012869 | 4012869 |

Analysis service

BEKO TECHNOLOGIES analysis service ensures compliance with the legal environmental regulations. Submitted condensate samples will be able to confirm the suitability of the process and the correct design of the plant in advance. The sender can be optionally informed about the residual hydrocarbon content and operating costs.

Reviews

There are no reviews yet.