Description

Safe

Always have an eye on the remaining capacity

- Permanent function monitoring

- Remote monitoring provided by network capability

- Automatic drainage

- Intelligent control FRC shows remaining capacity

- Fail-Safe-Mode

- Clear display of the available remaining capacity

Clean

Clean in every aspect

- Simple, clean and ergonomic change of cartridges

- No overflow of the system due to active operating principle

- Hermetically sealed cartridges

- No more contact with contaminants

- Integrated monitoring optimally utilizes the cartridges

- Absorbed oils are reliably retained

Modular

Full flexibility as modules grow with customer needs

- Easy adjustments to changing requirements for compressed air and condensate volumes

- Design according to service interval or compressor capacity

- One cartridge fits all QWIK-PURE models

- Facilitates procurement, inventory management and avoids wrong orders

New standards in condensate treatment

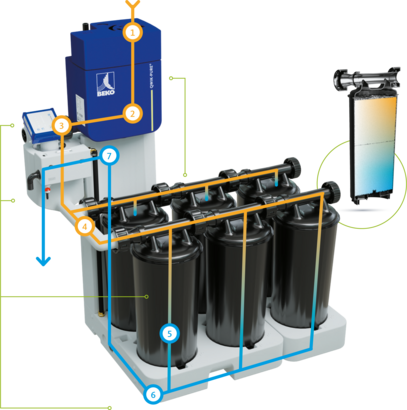

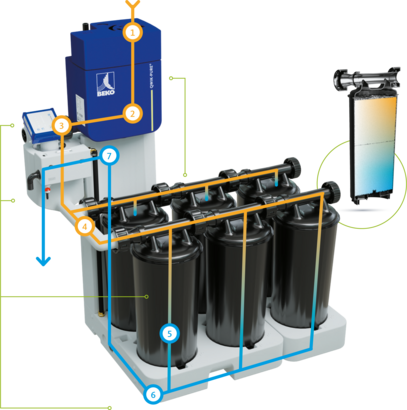

Active operation

Unique process and functional reliability

Conventional oil-water separators work according to the gravity principle and the condensate seeps through the filter medium. With the QWIK-PURE the condensate is actively forced through the pre-filter and main filter with light blasts of compressed air. During this process, the cartridge is permanently filled with liquid. This means that nothing can dry out and form impermeable boundary layers. On the other hand, there are hardly any unpleasant cultures with which the operators or service personnel can come into contact.

Consistently hygienic

Thanks to the hermetically sealed design, neither users nor service personnel come into contact with the substances absorbed inside. Everything that has been retained in the pre-filter and main filter reliably remains here and does not contaminate people in the vicinity or the discharged treated condensate.

Fail-Safe Mode

For power and compressed air loss

The integrated FRC control reliably displays the current remaining capacity of the cartridges and automatically monitors when condensate needs to be forced through with light bursts of compressed air. If there are problems, measures are initiated independently, and an alarm is triggered. In this case, the QWIK-PURE® continues to operate like a conventional gravity separator.

One cartridge fits all QWIK-PURE models

All QWIK-PURE units use the same cartridges, so storage space can be used more efficiently. Only one size needs to be stocked in the appropriate quantities.

Ergonomically designed

When developing the cartridges, we primarily thought about the users: The inlet tube, for example, was designed as a handy and stable handle so that the cartridge can be transported and mounted comfortably. Thanks to the controlled drainage, even a fully saturated cartridge

weighs less than 25 kg.

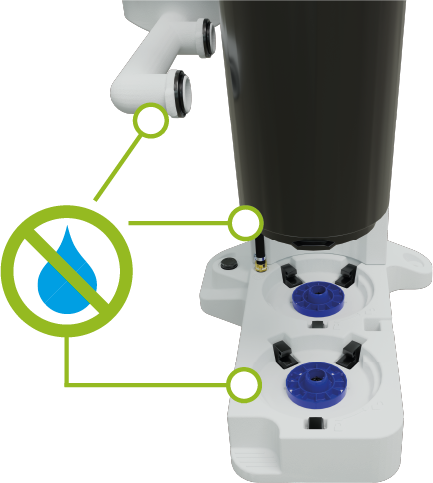

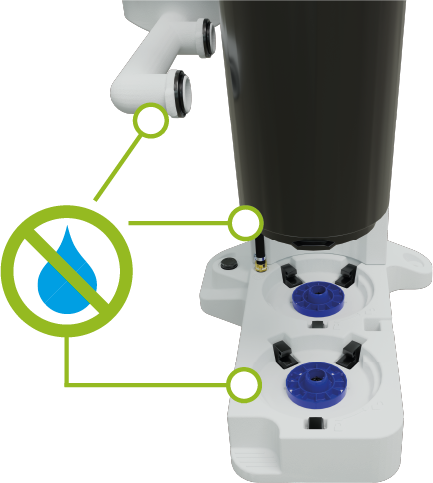

Clean cartridge exchange

A closing valve is integrated in the base so that nothing drips onto the floor after the cartridge has been changed. The supplied blind plugs for the upper openings ensure that there is no spillage of liquids whatsoever.

QWIK-PURE simply grows with you

Thanks to its modular design, the QWIK-PURE simply grows with the user – with just a few simple steps, it can be adapted to meet both higher and reduced requirements. This not only creates confidence when taking decisions, but also makes it very easy to create additional safety reserves or to adapt the service intervals to other service activities.

QWIK-PURE 10 to 15

Intelligent control

Here, the digital electronic unit FRC as well as the reservoir and the measuring chamber are retrofitted. As a result, active separation is achieved and the capacity is then increased to 15 m³/min. A new cartridge is also included in this set.

QWIK-PURE 15 to 40

More performance

The second cartridge doubles the performance. This requires an enlarged measuring chamber, a larger base plate and the second cartridge incl. piping. All components as well as four new cartridges are included in this expansion package. The new capacity after the retrofit is 30 m³/min.

QWIK-PURE 30 to 60/60 to 90

Easily expandable

The supplementary unit is simply plugged in at the side. By means of the control on the FRC, the extended capacity is entered and the additional capacity is already available. In addition to the base plate, 4 or 6 new cartridges are included in this package. Thus, the new capacity of the QWIK-PURE is 60 m³/min or 90 m³/min.

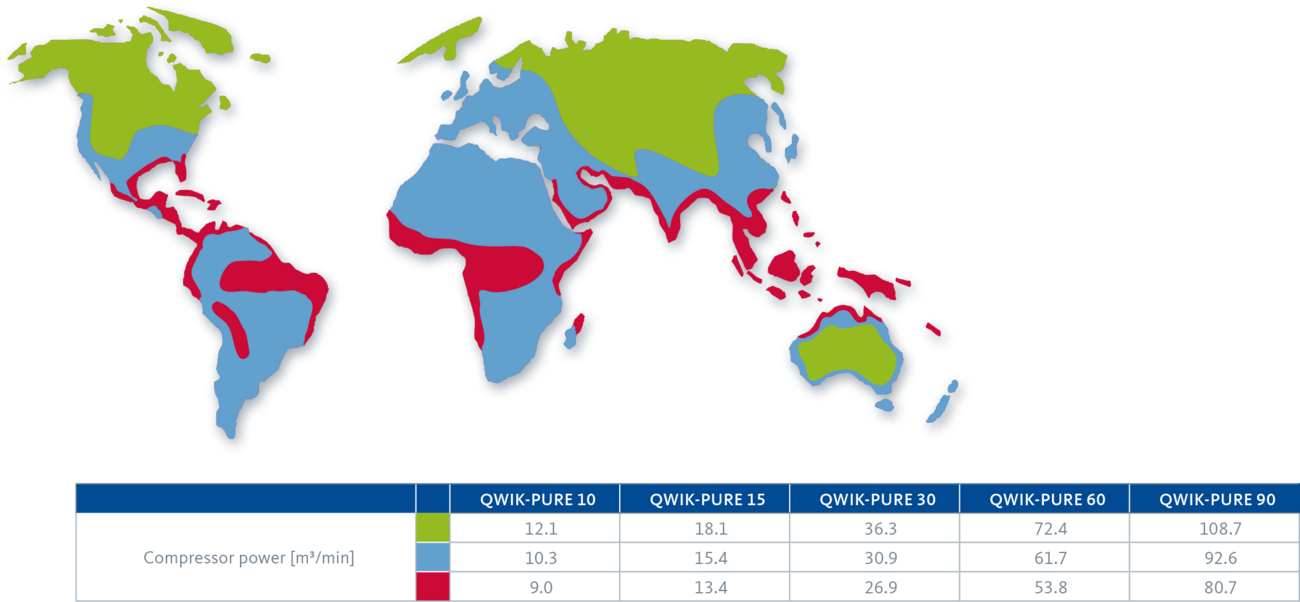

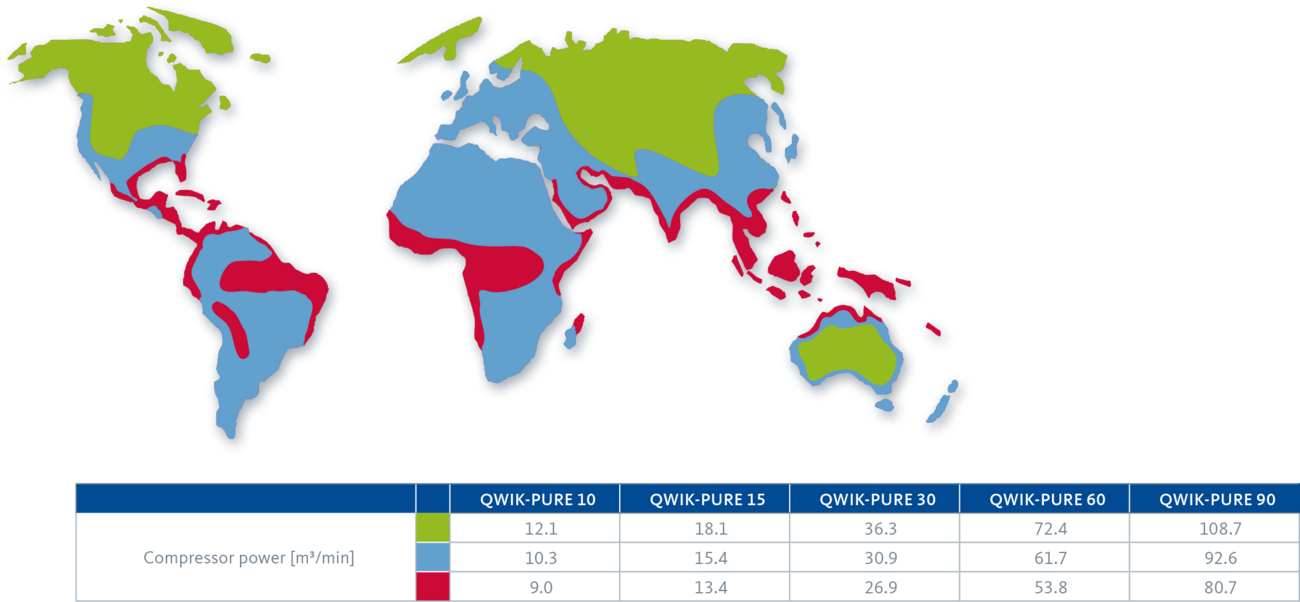

According to compressor capacity

Due to the unique active mode of operation of the QWIK-PURE, the compressor capacity and the climate map are sufficient to select the best possible oil-water separator. The compressor type and the compressor oil used are no longer used as a sizing factor.

Sustainable, efficient and user-friendly

Separating condensate and water incurs costs for compressed air and electricity. However, since the new QWIK-PURE system relies on just one cartridge for all models, less frequent service calls and lower storage costs can lead to a significant increase in efficiency. Eliminating the use of activated carbon here helps reduce CO2. The associated savings factors over many years result to an attractive Total Cost Ownership (TCO).

The focus is on operator safety Reliable protection of users from critical cultures and substances, but also ergonomic handling and ease of operation were particularly important to us during development, as they are elementary prerequisites for trouble-free operation over many years.

The handling of the QWIK-PURE simply explained

Capacity expansion

If the condensate treatment requirements change, the system can be modularly adapted.

Turbidity control

According to the DIBt approval, a manual optical turbidity check of the treated condensate must be carried out regularly. The sampling valve and the sample tube are easily accessible.

Convenient change

Inserting and changing cartridges is convenient and ergonomic due to the low base plate and the weight of max. 25 kg.

Easy navigation

The FRC is the basis for navigation and operation of the QWIK-PURE.

QWIK-PURE Function Video

Conventional oil-water separators work according to the gravity principle and the condensate seeps through the filter medium. With the QWIK-PURE® the condensate is actively forced through the pre-filter and main filter with light blasts of compressed air. During this process, the cartridge is permanently filled with liquid. This means that nothing can dry out and form impermeable boundary layers. Secondly, there are hardly any unpleasant cultures with which operators or service personnel can come into contact. This is controlled by the intelligent FRC control unit, which processes a wide range of indicators.

The new oil-water separator product portfolio

As experts for the entire compressed air treatment with decades of experience, we at BEKO TECHNOLOGIES know our way around condensate technology in particular. We understand the interrelationships and interactions between the components, which enables us to provide you with optimum advice. In condensate treatment, we set standards 40 years ago with the first generations of ÖWAMAT oil-water separators.

We are now doing this again with the first active oil-water separator QWIK-PURE. This range is extended by the static separators ÖWAMAT 10 and 11 as well as the expandable QWIK-PURE 10.

Sizes at a glance

| Technical data | QWIK-PURE 10 | QWIK-PURE 15 | QWIK-PURE 30 | QWIK-PURE 60 |

|---|---|---|---|---|

| Active functioning | No | Yes | Yes | Yes |

| Max. condensate flow | 12 l/h | 19 l/h | 38 l/h | 76 l/h |

| Max. operating pressure | / | 16 bar(ü) | 16 bar(ü) | 16 bar(ü) |

| Min./max. operating temperature | +5 … +50 °C | +5 … +50 °C | +5 … +50 °C | +5 … +50 °C |

| Relative humidity of the environment | ≤10 … 80 %, without condensation | ≤10 … 80 %, without condensation | ≤10 … 80 %, without condensation | ≤10 … 80 %, without condensation |

| Operating weight | 50 kg | 55 kg | 100 kg | 180 kg |

| Min./max. operating pressure | / | 3 … 15 bar(ü) | 3 … 15 bar(ü) | 3 … 15 bar(ü) |

| Purity class, compressed air | / | 2:4:2 | 2:4:2 | 2:4:2 |

| Operating voltage | / | 90 … 264 VAC / 24 VDC | 90 … 264 VAC / 24 VDC | 90 … 264 VAC / 24 VDC |

| Frequency range | / | 50 … 60 Hz | 50 … 60 Hz | 50 … 60 Hz |

Reviews

There are no reviews yet.